The City of Franklin, City of Muskego, Milwaukee Metropolitan Sewage District (MMSD), and Ruekert & Mielke, Inc. (R/M) worked together to resolve a severe odor issue from the Ryan Creek Interceptor (RCI) along West Ryan Road in the City of Franklin.

Franklin constructed an interceptor from the western part of the City eastward to the MMSD Metropolitan Interceptor Sewer (MIS) system. The interceptor was needed to serve additional development in Franklin.

Additional benefits of the interceptor Included:

A more efficient route of sanitary sewerage from the City of Muskego to MMSD MIS where more capacity was available

Accepting wastewater from seven Muskego lift stations where there were station capacity restrictions

Odors were anticipated during the design of the interceptor project since one Muskego lift station pumped landfill leachate through the Muskego collection system to MMSD.

The main way to address this anticipated problem was to construct the interceptor of PVC-lined reinforced concrete pipe with continuously welded joints. In addition, the RCI concrete manholes were lined with an epoxy coating system to minimize the occurrence of microbiological-induced corrosion from sulfuric acid – a byproduct of hydrogen sulfide, on the surface of the concrete.

Shortly after the interceptor was put online, odor complaints from eight homes on West Ryan Road started. The homes are connected to a short collector sewer and then to the RCI. Franklin investigated and there were no plumbing defects in the homes leading to the odors. Because of the odors, the RCI was taken offline with sewage being routed through the original collection system through the City of Muskego.

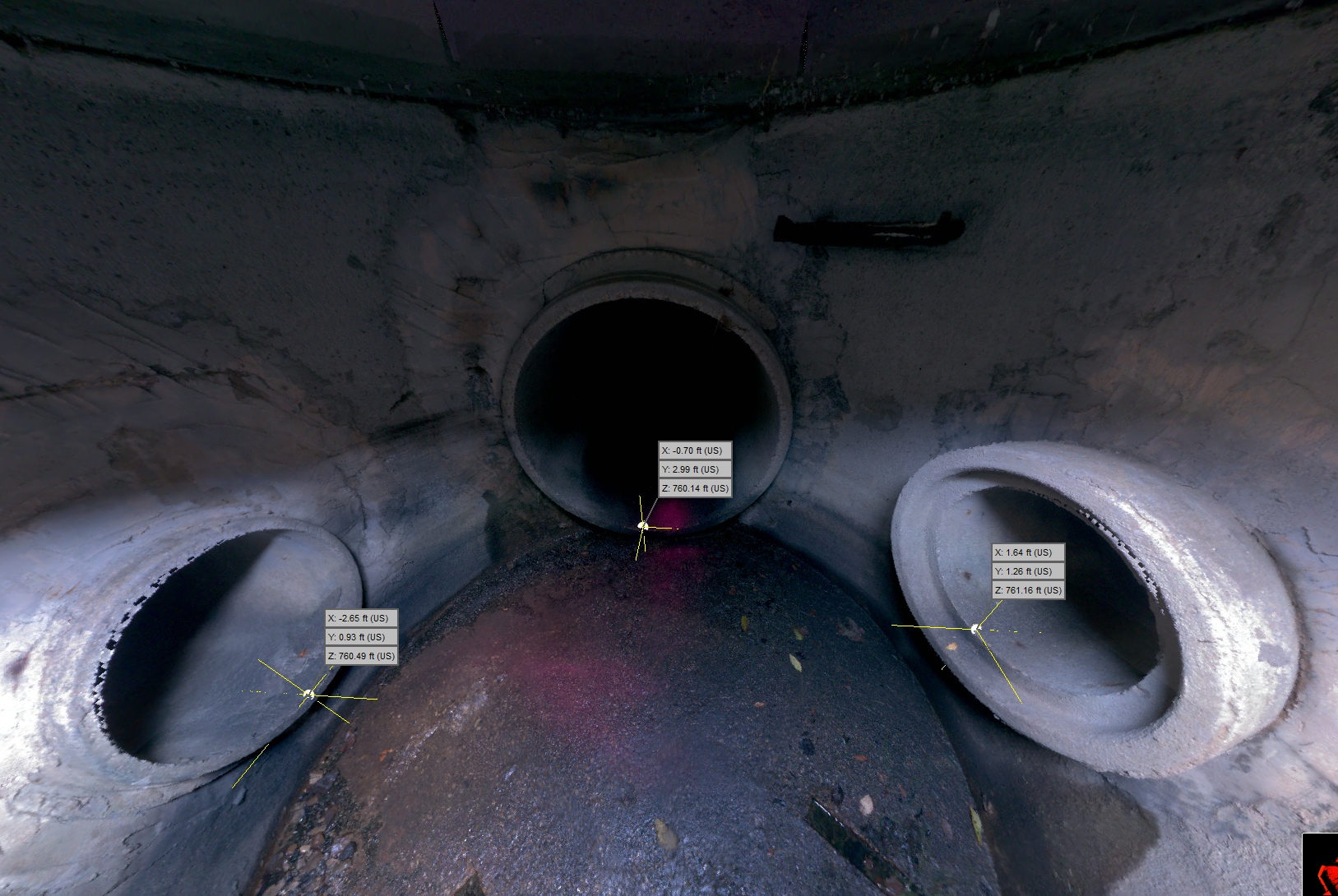

Mixer Drop Device

Franklin conducted a study on the best way to control odors. Franklin and R/M anticipated that a phased approach to control the odors may be necessary.

First Approach

The first approach was to aerate the sewage with a counter-current mixer drop pipe device that fits in the upstream RCI manhole. The advantage of this device was that it required no mechanical, chemical, or electrical components. As the wastewater dropped through the device, air was entrained into the sewage oxidizing the hydrogen sulfide. Air release pipes were also installed along West Ryan Road to allow air to enter and leave the interceptor. The original RCI design was extremely airtight. The air release pipes allowed the hydrogen sulfide to off-gas from the interceptor. Odor control caps with media were installed at the ends of the air-release pipes to minimize odors. The changes were implemented, and the odors in the problem area were reduced although they were not eliminated.

Dry Scrubber and Standby Generator

The City and R/M further investigated and determined that the prevalence of landfill leachate from a second landfill downstream of the initial odor area was a key part of the problem. The odors were most prevalent on cold days. The warm temperature of the leachate relative to the surrounding cold air in the mostly empty interceptor caused a pressure differential and natural draft in the pipe headspace. The draft produced air flow going upstream in the interceptor creating significant positive pressure in the residential plumbing systems which was a major source of the problem.

Second Approach

For the second approach to control odors, a dry scrubber was installed to provide negative pressure in the interceptor to overcome the natural draft in the pipe. The scrubber was in an area where an air release pipe was added to the interceptor, so no additional excavation was required. The scrubber drew air in through an RCI manhole and forced it through a specialty chlorine-impregnated media. The “clean air” is exhausted from the scrubber through a top pipe. The scrubber was wrapped with a specialty pattern to blend aesthetically with the surroundings. The scrubber was equipped with a backup generator to allow continuous operation when normal utility power is interrupted.

Duckbill Check Valve

In addition, duckbill-type check valves were installed in the RCI and the collector sewer. The valves, which are normally closed, reduced the pipe headspace air flow in the upstream direction toward the area susceptible to odors. The valves opened for a limited time upon 4- 8 inches of backwater against the valves. After the wastewater drains through the interceptor, the valve snaps closed again.

The combination of these three devices; a manhole drop mixing device with air valves, a chemically enhanced media scrubber, and duckbill-type check valves significantly reduced odor issues from the interceptor and allowed the interceptor to be placed in permanent service for current and future sewer users.

R/M Can Help!

Is your community experiencing interceptor odors? For more information, please contact Dave Arnott.

about the author

dave w. arnott, p.e.

Team leader / senior project manager

Dave has extensive experience in the planning, design, and construction project management of wastewater treatment facility renovation and upgrade projects. Areas of expertise include treatment processes, hydraulics, mechanical equipment, and wastewater disinfection. He also has experience in sanitary and water pumping station design and sanitary sewer wet weather facilities.